DL-based Error Mitigation for Exoskeleton

The FIBlock is able to generate various types of highly adjustable CPS faults. We demonstrated the performance of the FIBlock on a Simulink case study representing a lower-limb EXO-LEGS exoskeleton, an assistive device for the elderly in everyday life. In particular, we discovered the spatial and temporal thresholds for different fault types. Upon exceeding said thresholds, the Dynamic Movement Primitives-based control system could no longer adequately compensate errors. We proposed a new Deep Learning-based approach for system failure prevention. We employed the Long Short-Term Memory (LSTM) network for error detection and mitigation. Error detection is achieved using the prediction approach. The LSTM models are mitigating the detected errors with computed predictions only when they were subject to the imminent failure (i.e., exceeded the aforementioned thresholds).

According to the previous results, the control system can effectively compensate sensor freeze and stuck-at-0 signals only when their duration is no greater than 0.3 seconds. So it is clear, that more robust dedicated error mitigation solution is needed. For that, DL-based error mitigation technique was employed. The developed system increased on average this maximum tolerable fault duration from 0.3 seconds up to 1.25 seconds. In terms of time delay, for the presented solution it takes on average 0.035 seconds to predict one step.

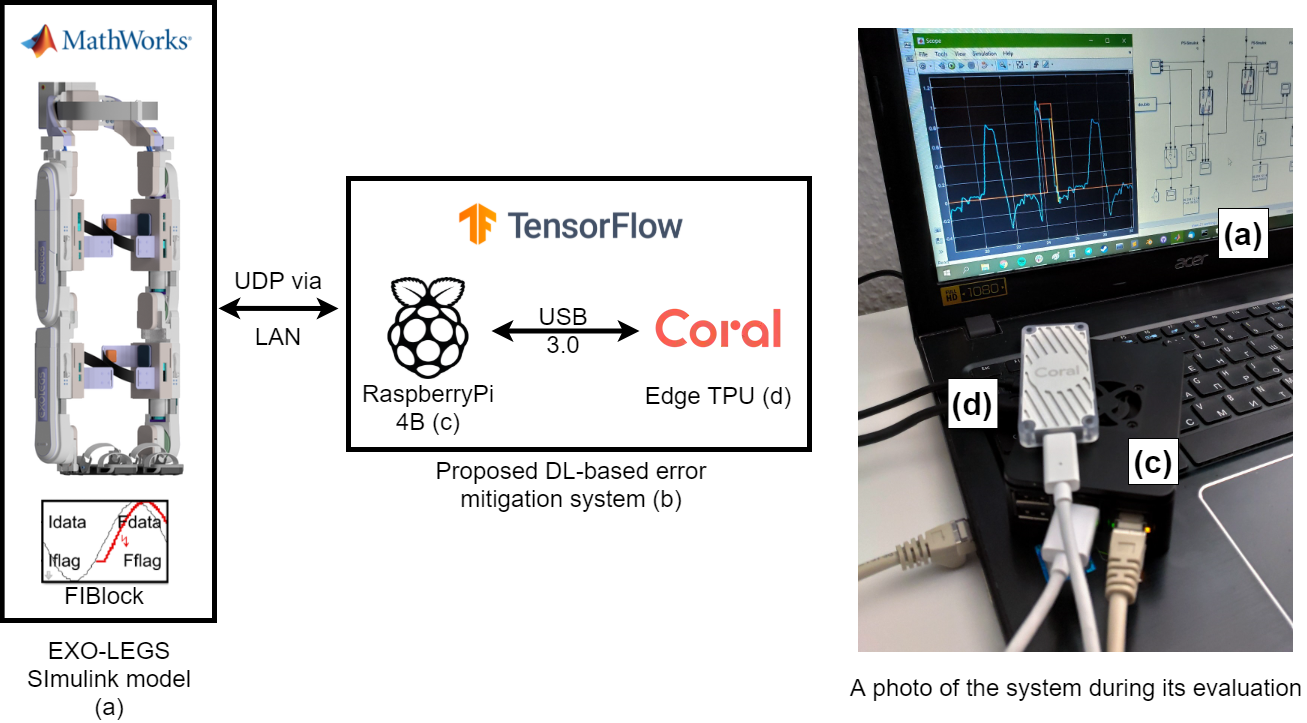

To compare our approach with previous findings, we trained two LSTM models on angular position and angular velocity signals. For evaluation, we performed fault injection experiments with varying fault effect parameters. The ’Sensor freeze’ fault was injected into the angular position sensor, and the ’Stuck-at 0’ fault was injected into angular velocity sensor. The presented Deep Learning-based approach prevented system failure even when the injected faults were substantially exceeding thresholds. In addition, reasoning for data access point choice has been evaluated. We compared two options: (i) the input data for LSTM is provided from the sensor output and (ii) from the controller output. We deployed the trained LSTM models on an Edge Tensor Processing Unit. For that, the models have been quantized, i.e. all the 32-bit floating-point numbers (such as weights and activation outputs) were converted to the nearest 8-bit fixed-point numbers and converted to the TensorFlow Lite models. The Coral USB Accelerator was coupled with a Raspberry Pi 4B for signal processing. The result proves the feasibility of the proposed method. Because the LSTM models were converted to the 8-bit integer TensorFlow Lite models, it allowed firm real-time error mitigation. Furthermore, the light weight of the system and minimal power consumption allows its integration into wearable robotic systems.

Schematics of the DL-based Error Mitigation system.

Schematics of the DL-based Error Mitigation system.

Fault Injection Block

Model-based fault injection methods are widely used for the evaluation of fault tolerance in safety-critical control systems. They are recommended by modern industrial safety standards, including IEC 61508. This project is devoted to the developtment of the new model-based fault injection method implemented as a highly-customizable Simulink block called FIBlock. It supports the injection of typical faults of essential heterogeneous components of Cyber-Physical Systems such as sensors, computing hardware, and network.

The FIBlock GUI allows the user to select a fault type and configure multiple parameters to tune error magnitude, fault activation, and fault exposure times. Additional trigger inputs and outputs of the block enable the modeling of conditional faults. Furthermore, two or more FIBlocks connected with the trigger signals can model so-called chained errors.

Fault Injection Block enable conduction of the fault injection experiments for the model-based safety assessment.

FIBlock is available at GitHub and at MathWork website.

Attention! More detailed overview on FIBlock work with a test Simulink model is available in this article.

An example of a Simulink system with two FIBlocks.

An example of a Simulink system with two FIBlocks.

FIBlock GUI window with a faut injection parameters.

FIBlock GUI window with a faut injection parameters.

Autonomous Intelligent Aerial Secure System

Flatag Technology is based on our own metaheuristic sollution of general transportation problem. This revolutionary Intelligent algorithm will compute all needed information faster than any other.

Drones operated by Flatag Technology have swarming capability. They communicate with each other to avoid crushes and obstacles and will find the shortest path.

All you have to do is set up coordinates. If drones will running low on battery they will automatically return to the depot and all you need is to charge them. Drones will connect to each other and distibute computations.

Flatag drones are intelligent enough to fly all by themself. You don’t need to manually operate them. AI will do all this work for you. All you need is to charge the Flatag drones and set the destination ponts for each drone. They will distribute computing betwean each other to find the best way to achive your goals.